inventory

Generating Purchase Order from Sales Order

June 3, 2021

Article

It is a very common business practice that, whenever a firm receives a Sales order, on the basis of that sales order they generate a purchase order for their vendors (usually with the same product and quantity). VTiger 7 also supports this function and provide an option to generate a purchase order for every sales order in the system. Generating Purchase order from Sales Order makes the process of ordering inventory much simplies and more efficient in Vtiger CRM Moreover, if you need advanced features in the sales order and purchase order module, then do check Item Detail Customizer extension Generating Purchase order from Sales Order To generate the purchase order for a sales order, select any Sales Order, click on more and select the Create Purchase Order option ins a sales order Example We will take a practical example to explain it in detail Lets generate a sales order of 20 wallets.

Inventory Deduction in Vtiger CRM

May 23, 2021

Article

The rule for inventory deduction is that once a Sales Order is processed, the quantity of inventory should be decreased by the amount of sales order automatically for example You have “Wallet” as a product and the total quantity of available wallets is 15. You processed a sales order of 5 wallets, so the inventory left for the products should be 10 and this is done automatically. But, VTiger does not work like this. In VTiger the deduction in the inventory will only takes place once you generate the invoice. Lets take a practical example to understand this process A company has 20 wallets in stock They processed a sales order of 5 wallets But, Vtiger stills shows 20 wallets in inventory To update the inventory, you will have to generate the invoice. Once, you generate the invoice the inventory available in the products will be reduces by the amount

Inventory Management in Vtiger CRM

March 23, 2021

Article

Inventory is a major component of product based businesses. Mismanagement of inventory can cause huge losses both in term of reputation and monetary value. There are numerous instances when business loss huge sum of money because of inventory mismanagement. Inventory management is one of the biggest challenges faced by the expanding businesses. For example, a local sports goods business expanded and opened a new branch in another city. Now they have inventory stored in multiple locations which is being sold in two different cities. So, with the expansion, managing inventory also became complex and if not handled properly can cause serious troubles. VTiger CRM provides comprehensive inventory management tools, in the shape of its inventory add on. Following are some of the disadvantages of poor inventory management Overstocking/Understocking: Poor inventory management causes overstocking. If you do not know how much quantity of a product should be ordered, it is very

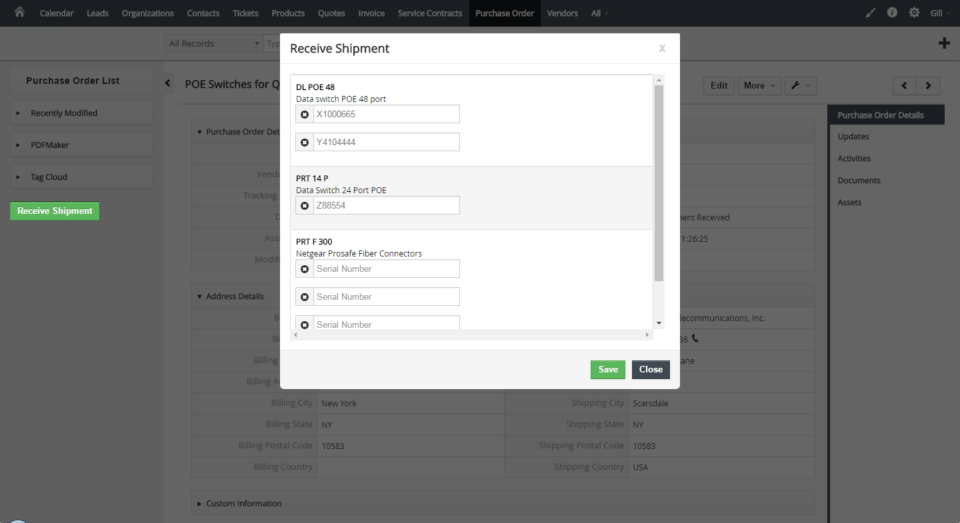

Receiving Purchase Order & Creating Assets in VTiger

July 19, 2016

Article

Out of the box VTiger has a built-in Purchase Order handling tool that allows users to create Purchase Orders, print or email them to the Vendor as well as link them back to Sales Order or an Invoice. In addition, there’s logic behind each Status, e.g when the Purchase Order status is changed to “Received”, it will ‘receive’ the items and update the “Qty. On Hand” for each item/product. All of the functionality is great. However, it is missing one of the most important features – keeping track of received items/assets. We came up with a solution that not only allows users to update the “Qty. On Hand”, but also enables to enter the serial number for each item and create it as an asset. It also supports a bar code scanner, all the user has to do is to put the cursor on the first item box and start scanning – the serial numbers will be